repairing healthcare in Rwanda

Process visualizations for the upkeep and repair of medical equipment in distant work locations

Collaboration with representatives of Duke University, IKEA and the World Health Organization

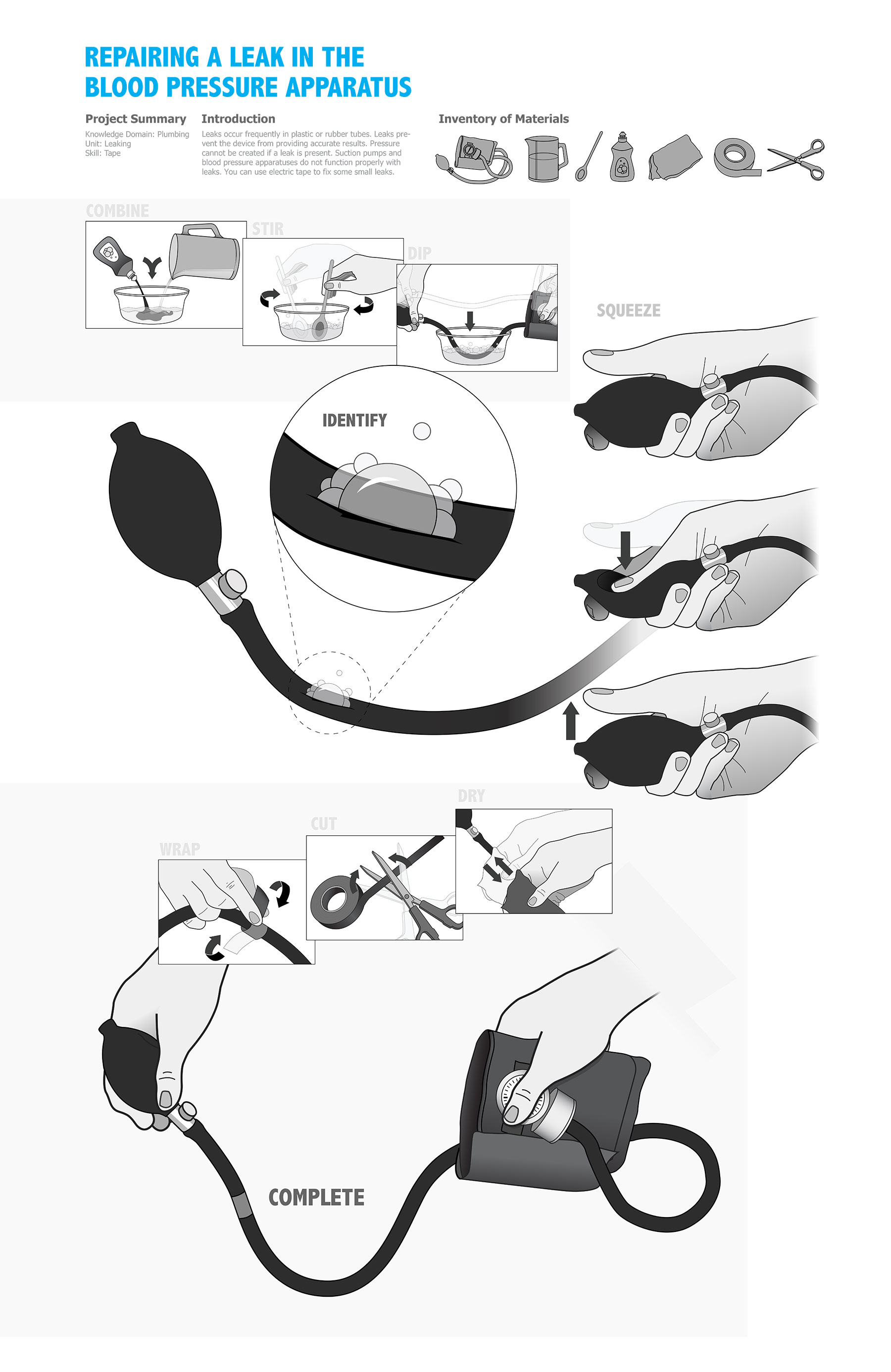

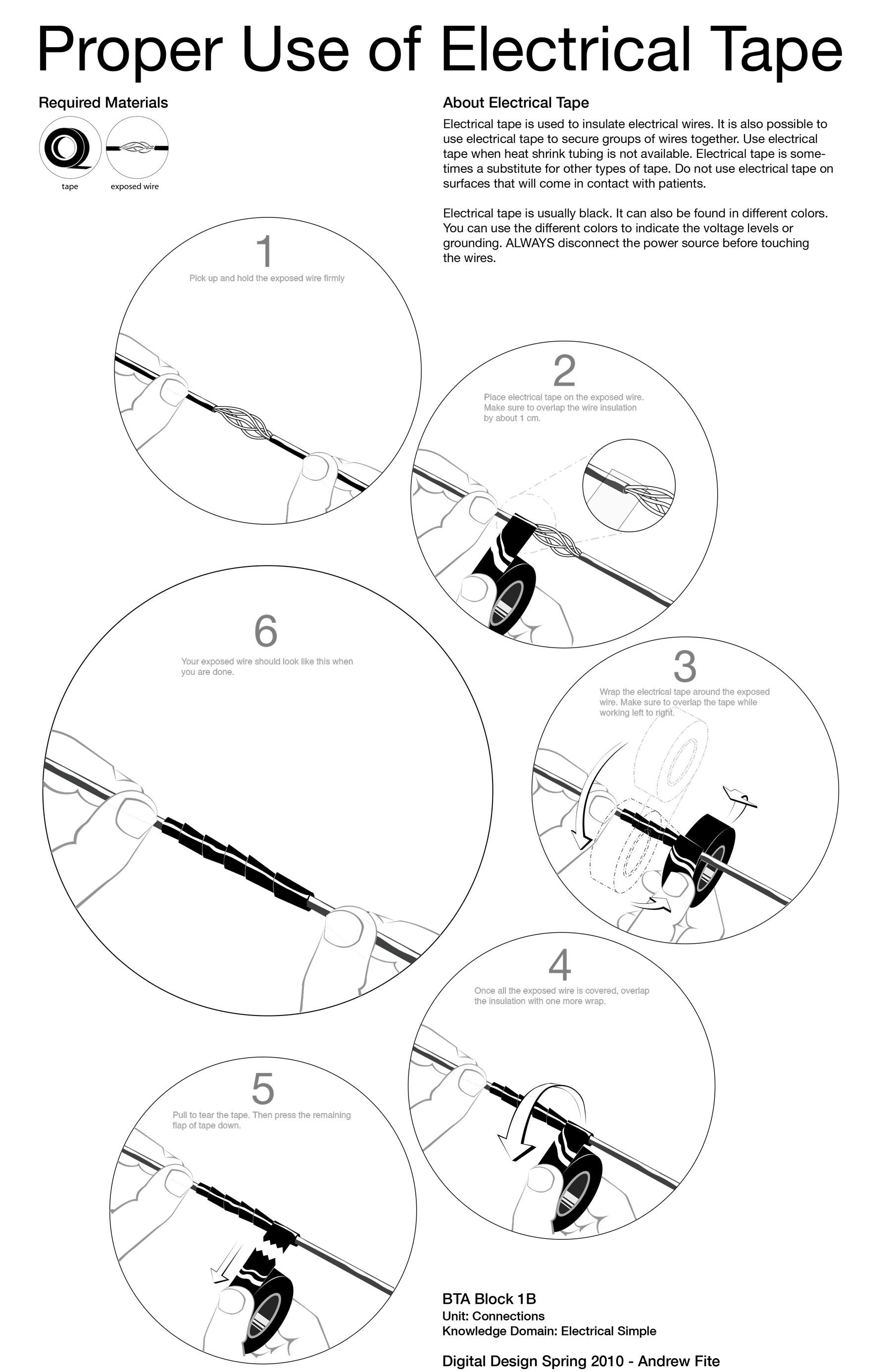

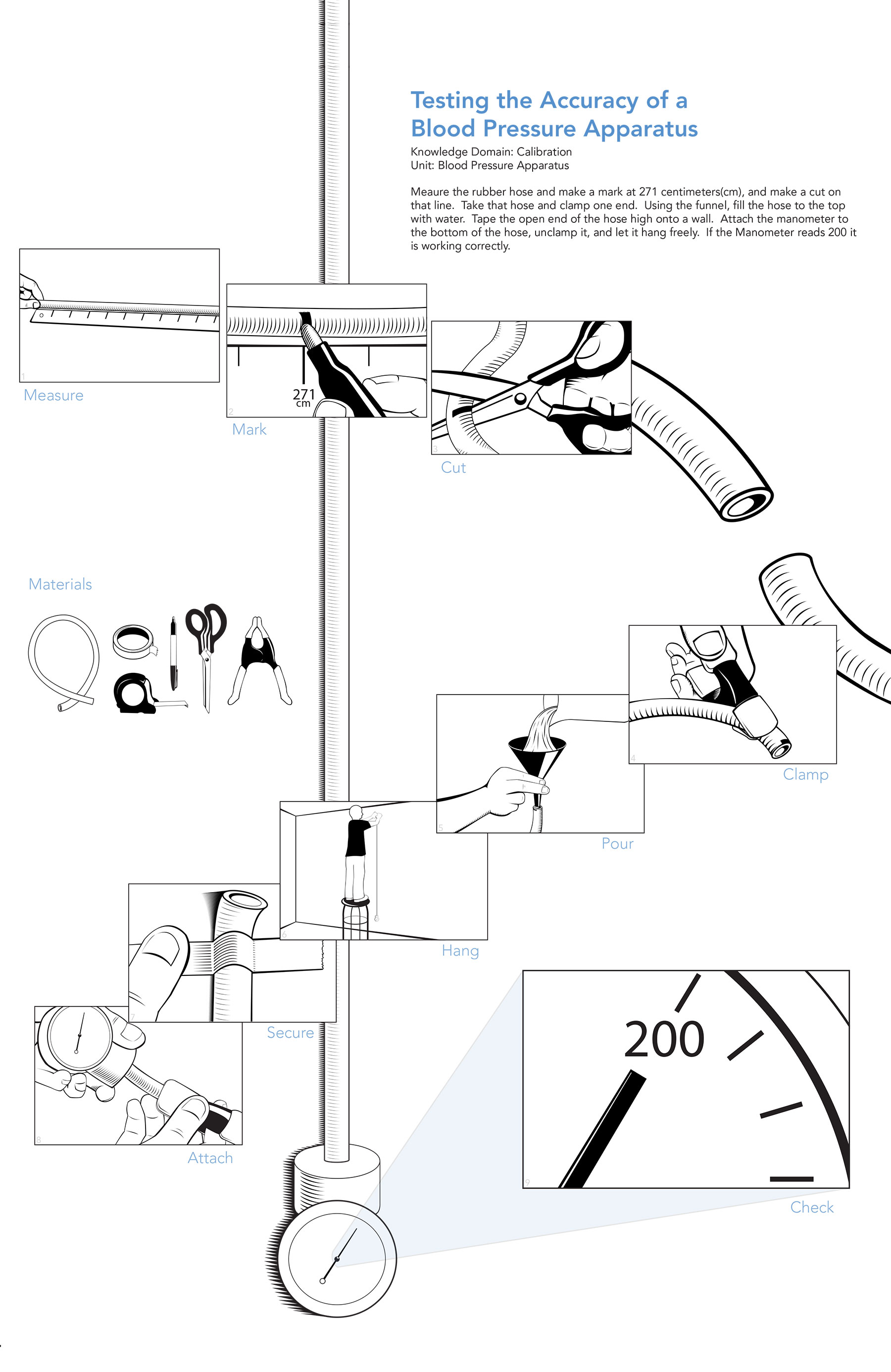

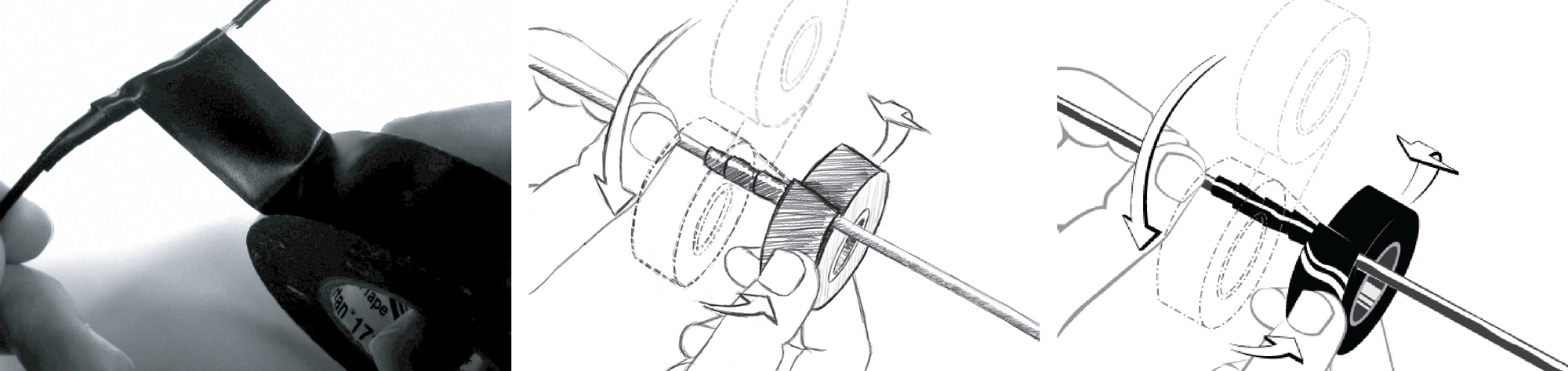

Improve the visual communication of 30 repair procedures that can fix 70% of equipment failures

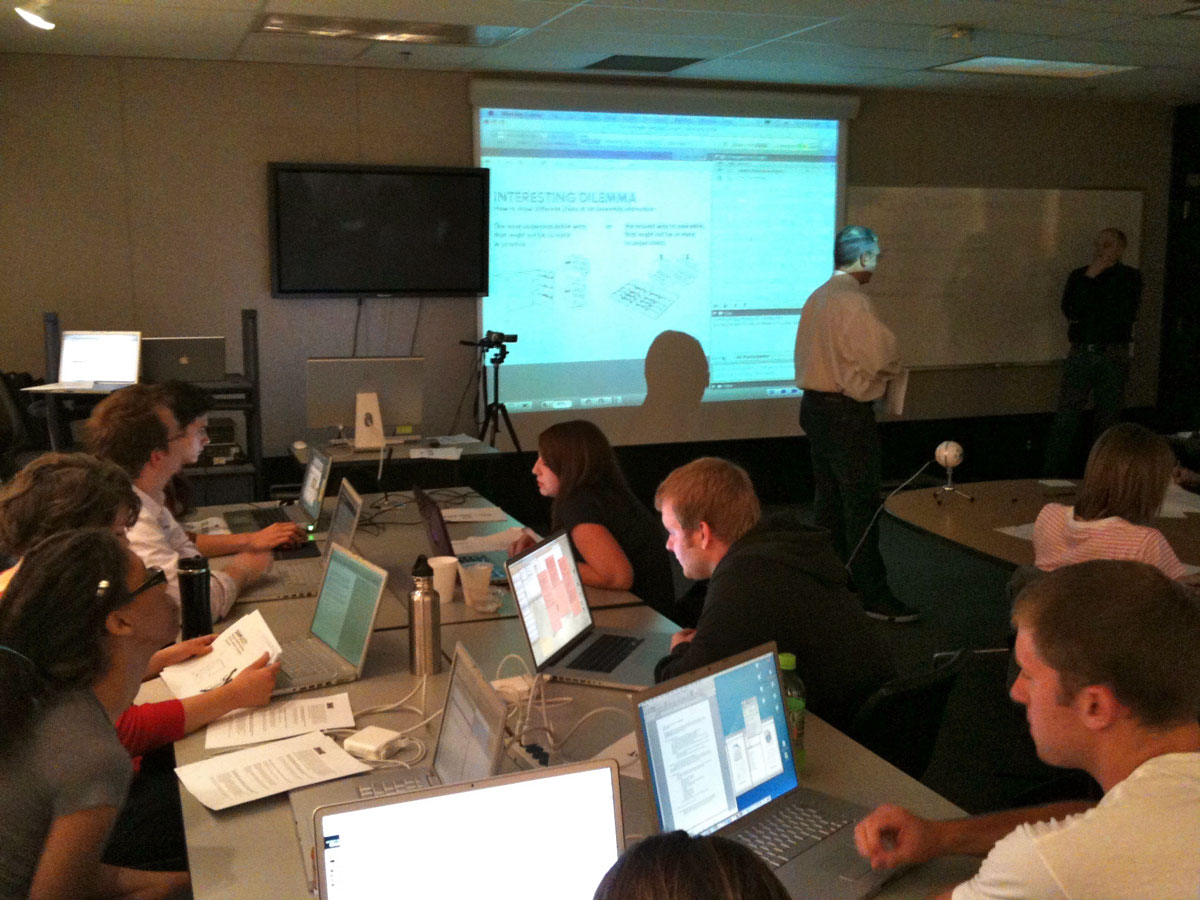

Using techniques in a series of lessons developed by Duke University, sixty percent of medical equipment failures in Rwanda could be remedied by locally trained technicians. The lesson materials are rich with descriptive content, but fall short of depicting a clear, step-by-step diagnostic and repair procedure. Design students at the University of Cincinnati endeavored to affect health care conditions a world away. Using technology, the class was able to communicate live with Duke, Rwanda and IKEA to conduct research. Project assignments guided the group through understanding local conditions, reenacting and documenting repair procedures, and finally presenting graphically accurate procedural solutions.

—Graphic solutions to medical equipment diagnostic and repair techniques (R. Brilli, A. Fite, B. Cushing, C. Garman)

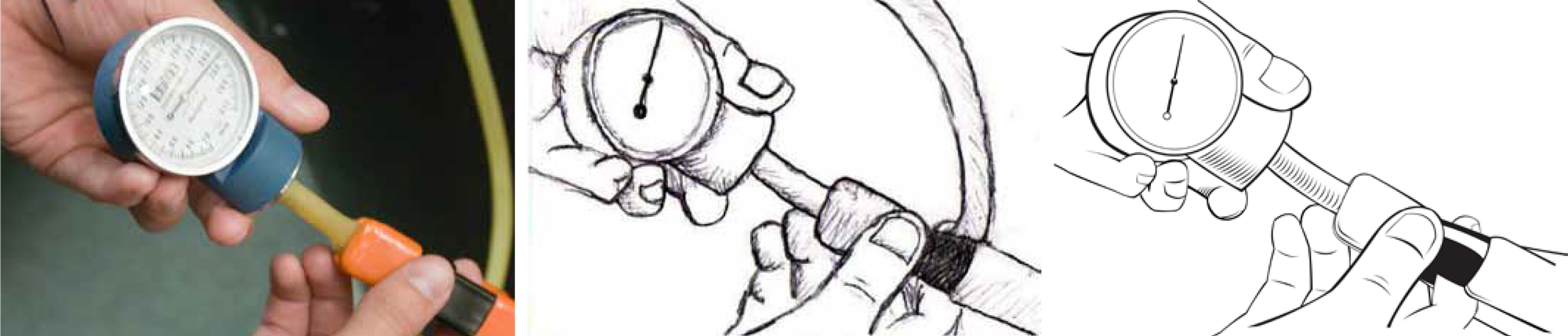

—Evolution from reenactment to digital illustration (C. Garman, A. Fite)

—Reenactment animatic to learn procedure and generate reference imagery (B. Zivich, A. Walton, M. Sallans)

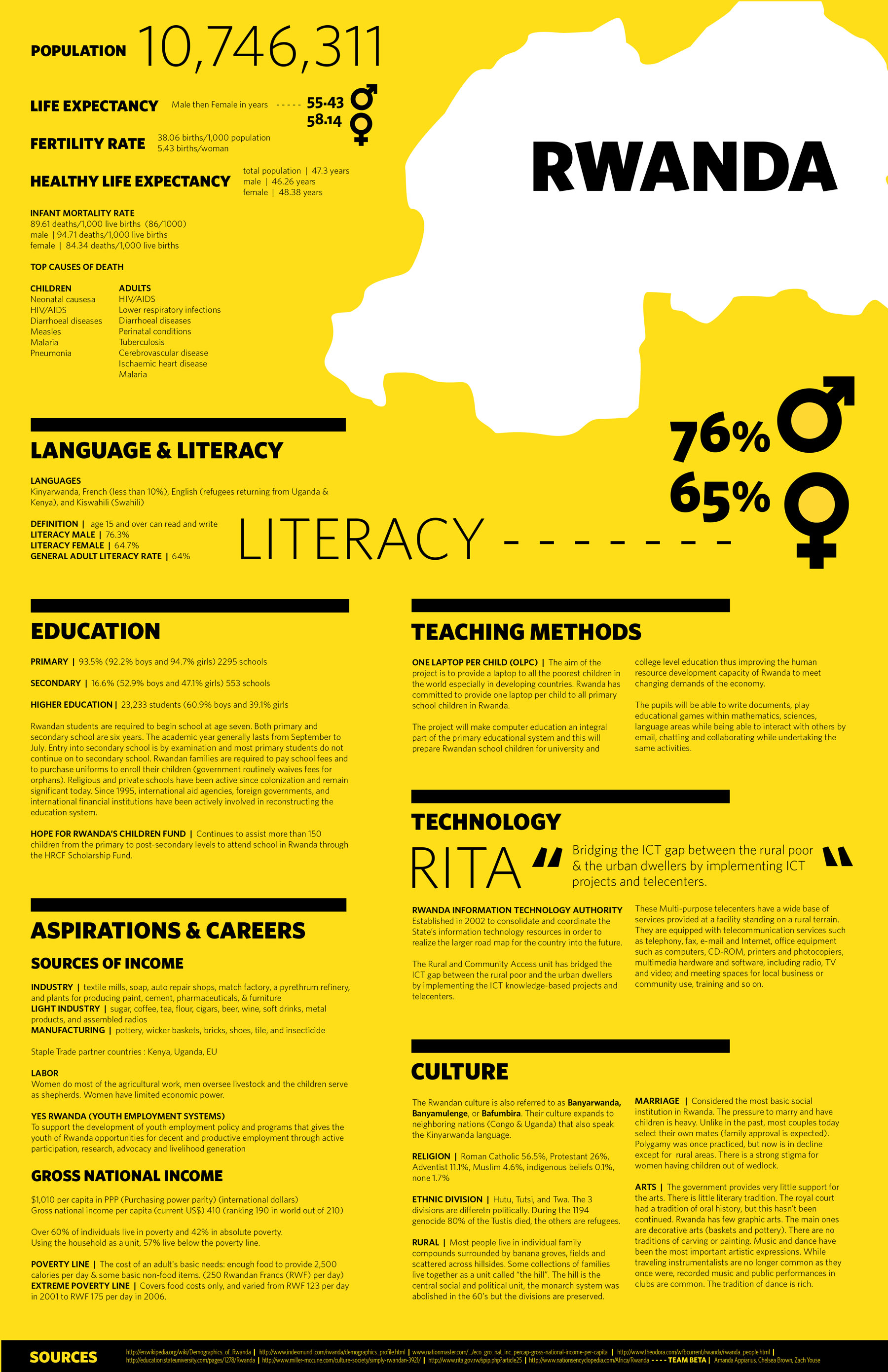

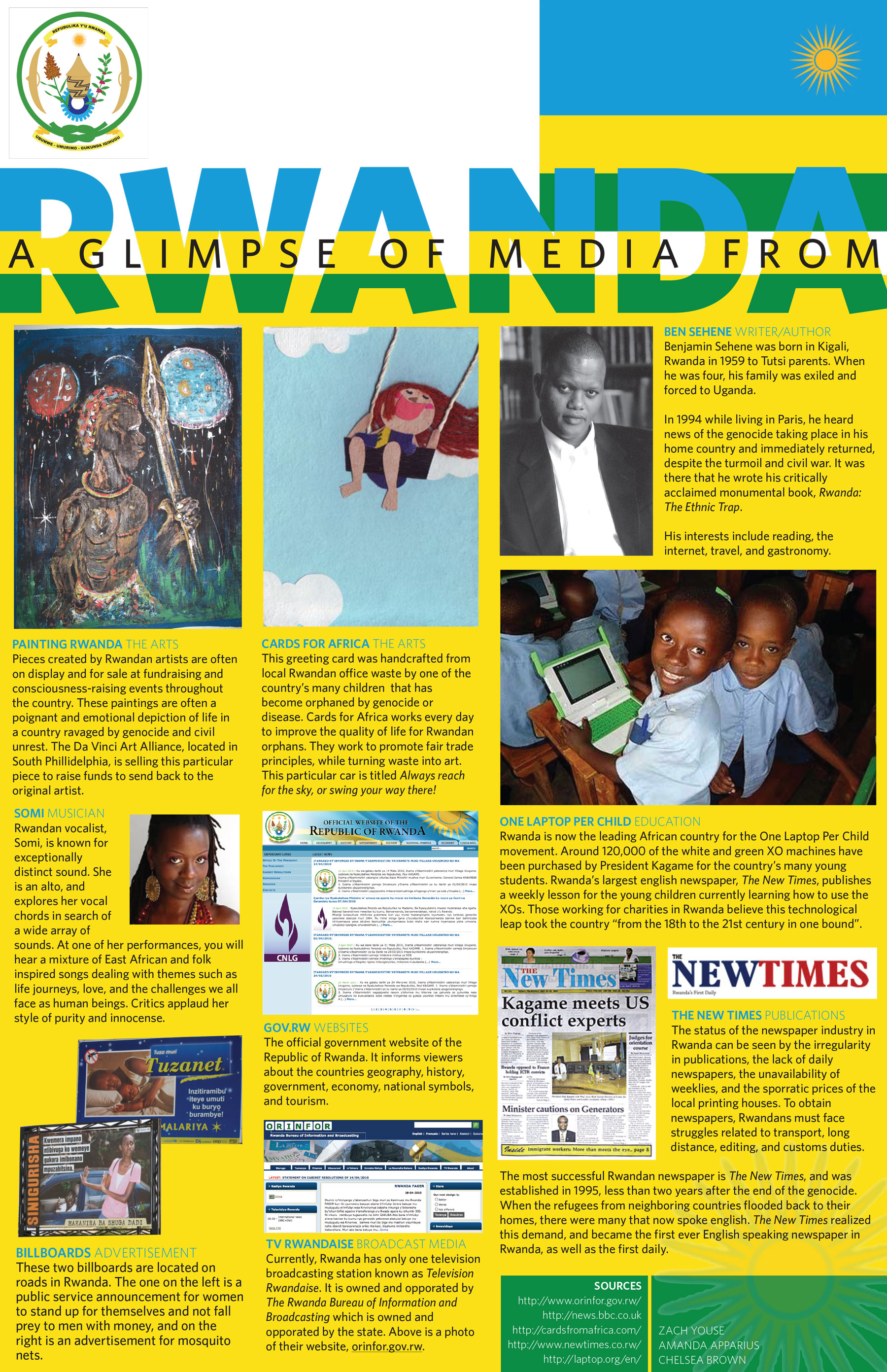

—Understanding the biomedical technician student in Rwanda (A. Appiarius, C. Brown, Z. Youse)

—Digital Design 3 students prepare to share concepts with IKEA team responsible for assembly instructions for all worldwide products